A unique technology for preventing gasoline evaporation has been developed in Russia.

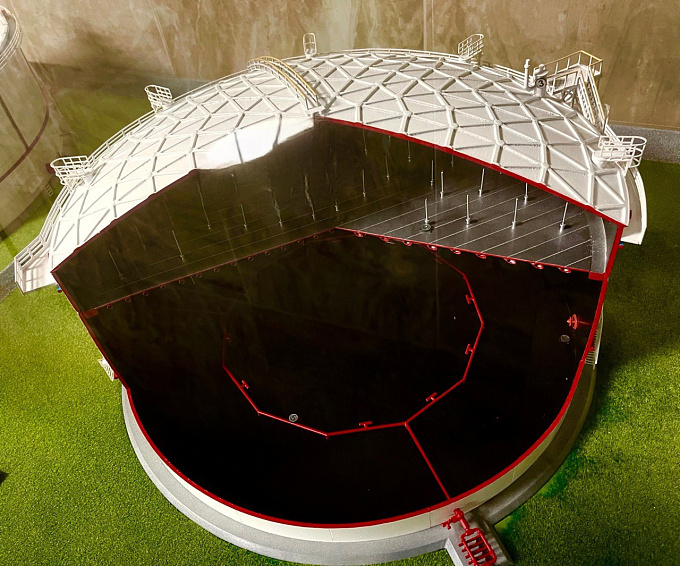

Scientists from the Gubkin Russian State University of Oil and Gas (National Research University) have discovered a way to combat gasoline evaporation in fuel tanks. The researchers developed a special paint for coating the walls of storage tanks that acts as a thermostat, reducing gasoline losses by almost 2-3% per year and reducing emissions of harmful volatile compounds into the atmosphere. The technology is unique in Russia and the world and will help save fuel in storage tanks, especially in warmer climates: Crimea, the Caucasus, the Krasnodar and Stavropol Krais, and the Rostov, Astrakhan, and Volgograd regions.

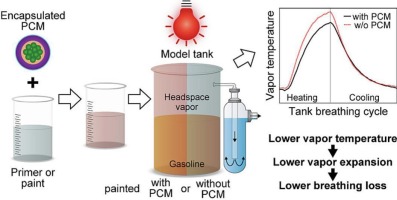

The coating contains microcapsules of paraffin (eicosane) encased in a polyurethane shell. These capsules act as heat accumulators: during the day, they absorb excess heat, preventing the formation of gasoline vapor, its heating, and its escape from the tank. At night, they release the accumulated heat, reducing cooling.

"The problem our development solves is known as losses from 'small breaths' in tanks. During the day, the tank walls are heated by the sun, the gasoline vapor inside expands, and is released into the atmosphere through a special valve. At night, when cooling, the vapor condenses, and the tank draws in outside air. This cycle repeats constantly, leading to significant fuel losses," noted Denis Voronin, head of the Laboratory of Functional Energy-Saving Hybrid Materials at the Gubkin Russian State University of Oil and Gas (National Research University).

The encapsulation of paraffins to create temperature-regulating additives is being actively studied worldwide. But Russian scientists are the first to propose using such additives to reduce gasoline losses in tanks from so-called 'small breaths' caused by average daily temperature fluctuations. The researchers placed paraffin (eicosane) in such capsules and then added them to standard tank coatings. Since the capsule content in the paint does not exceed 20%, the resulting coating retains its key performance properties.

"When daytime temperatures rise and there is a risk of overheating, the paraffin inside the capsules melts, absorbing excess heat and preventing the vapor-air mixture in the tank from expanding significantly. At night, during cooling, the paraffin hardens, releasing the accumulated heat and softening the temperature drop inside the tank. Thus, the coating smooths out daily temperature fluctuations inside the tank, reducing losses from 'small breaths,'" the scientist explained. Laboratory experiments with a model tank showed that the coating with microcapsules reduced the temperature of gasoline vapor by an average of 1.7 degrees Celsius over 480 day-night cycles. Calculations based on actual climate data for Russia for 2023 showed that for a large 5,000-ton tank, savings could range from 84 to 235 kilograms of gasoline per year (1.79 to 2.76%).

The most significant reduction in losses was recorded in regions with moderately warm climates, where daily temperature fluctuations coincide with the material's operating range (35-40 degrees Celsius). These regions included Crimea, the Caucasus, Krasnodar and Stavropol Krais, and the Rostov, Astrakhan, and Volgograd regions. Scientists note that the coating's effectiveness in other regions could be improved by encapsulating paraffins with a more suitable operating temperature.

Gasoline evaporation during storage is not just a technical problem, but a leak that impacts the economy and human health. It was estimated, for example, that in 2002, 58 million liters of fuel evaporated from gas stations in Canada—more than 14 liters of gasoline per day per station. In China, losses reached four kilograms per ton of stored fuel, and in some cases, they can reach up to 0.5% of the total volume. On a national scale, these figures are enormous.

Furthermore, evaporating gasoline releases volatile organic compounds, which cause smog and harm ecosystems and human health. These invisible vapors include benzene, a substance with a proven carcinogenic effect. Therefore, the problem of losses from "small breaths" in storage tanks remains pressing.